Desiccant Masterbatch

Today, recycled materials are highly used in many polymer products due to cost reduction and environmental concerns. Because of washing phase, these materials contain significant moisture. Additionally, some raw polymer materials, fillers, and pigments may also have high moisture content due to their polar nature.

Desiccant masterbatch, also known as de-foaming and absorbent masterbatch, is used as a moisture absorber in plastic, polymer, and nylon materials containing recycled materials or fillers in their formulation. The use of this masterbatch improves product quality and efficiency, increases rate of production, reduces energy consumption, enhances final product brightness, and prevents moisture-related problems such as fish eye porosity and windows in films. Desiccant masterbatch has absorbent materials that react irreversibly with moisture and form a material which is easily combined with polymer raw materials and does not cause any matt in the final product.

Advantages

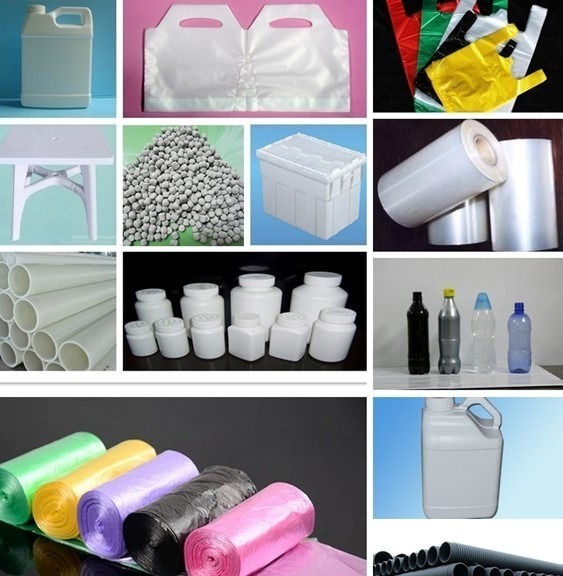

Desiccant masterbatch is used as a moisture scavenger and water-absorbing agent to remove moisture from raw polymer and recycled materials such as polypropylene and polyethylene (LDPE, LLDPE, and HDPE) in film production processes using blown or cast methods, injection molding, and blow molding. De-foaming masterbatch can address moisture-related problems that arise during plastic product manufacturing processes. The advantages of using this masterbatch include reducing and eliminating eye fish, reducing matt and increasing production rate, increasing product strength, reducing extruder corrosion, and improving mechanical properties. Additionally, eliminating bubbles in the production of garbage bags and nylon, eliminating porosity and holes in injection and extrusion processes, and removing gas during polymer production are among the advantages of using desiccant plastic absorbent masterbatch.

Desiccant masterbatch can be used with various additives such as black & white masterbatch, processing aid, Anti-UV, etc. in the recycling industry, such as processing aids, antioxidants, pigments, etc.

Using small amounts of Desiccant masterbatch (0.5 to 1.5%) is an easy and cost-effective way to remove moisture in the production of polymer plastic, nylon, sheets, and plastic parts, which saves energy and increases production speed and capacity. The masterbatch contains high-quality and very fine drying agents having high compatibility in their performance.

Aria Add 2180 is brand name of Aria Polymer Desiccant Masterbatch.

Feel free to be in touch with us for purchase or any advice.