Additive Masterbatches

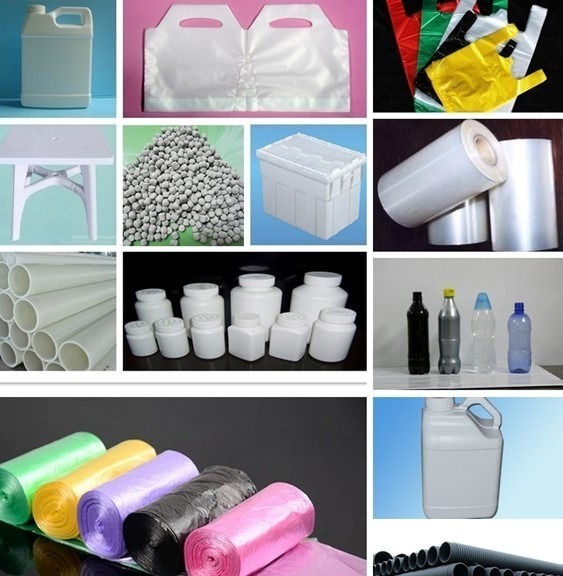

In recent years, polymer has been used as one of the most current raw materials for the production of various products and goods in order to meet the needs of communities and development of different scopes of human knowledge,

Each of the production and processing of polymer products, has specific requirements and for achieving a high quality product, the raw materials must have unique properties compatible with the process conditions and available equipment. On the other hand, due to the nature of the polymer as well as the fluctuation in properties of grades produced by petrochemical reactors, process instabilities may occur or the product produced does not have the desired quality. Improving the properties of polymer, correcting and resolving problems in the process, etc. are the most important challenges in the polymer industry, which always creates concerns for manufacturers.

Manufacturers of polymer products use Additive Masterbatches as a solution to this challenge. These materials, with their special performance, are able to modify the properties and behaviors of polymer, especially in molten state, improve the quality of the product, in terms of physical, mechanical and optical properties, and solve the problems of polymer processing to facilitate the process, increase machinery life time and reduce its depreciation, increase production rates, etc.

The additives are highly varied and depending on the type of process, the expected properties and required quality of the product. They can be added to the formulation in varying amounts. UV light stabilizers, slip and anti-block, anti-oxidant, anti-static, MFI Modifier, impact resistance enhancer, optical brightener, process aid, anti-warpage and shrinkage, etc. are among the additional masterbatches available in this field.

Aria Polymer Pishgam Company has designed and produced masterbatches containing high quality additives by means of the latest methods in the world.