Polymer Fibers (Part 1: Introduction and Common Fibers)

Introduction

Fibers are part of our daily lives. Reflecting on their surroundings can understand their full impact on society, from everyday uses such as clothing and carpets to artificial grass, fiber-reinforced composites in sporting goods (rackets, golf clubs, etc.), boats, civil engineering, aerospace and military applications such as aircraft and rocket.

There are many different types of fibers; most of them have diameters greater than one micrometer, and they can be divided into polymer fibers and non-polymer fibers. Polymer fibers include synthetic polymer fibers and natural polymer fibers. Synthetic polymer fibers are made from polymers synthesized from raw materials, such as petroleum-based chemicals or petrochemicals. Generally, synthetic polymer fibers are created by forcing, usually through extrusion, polymers through small holes (called spinnerets) into air or other mediums to form filaments. Natural polymer fibers include those produced by plants and animals. They are typically biodegradable and can be classified as natural cellulose fibers and natural protein fibers. Non-polymer fibers are those that are not made from polymers, and include carbon, glass, ceramic, metal, and composite fibers, etc. [1]

We first define some terms commonly used in the field of fibrous materials. We should add that some of these definitions are expanded upon later in here . However, before one can define the term fiber, one needs to define the most important attribute of the fiber that serves to define a fiber, namely the fiber aspect ratio. The aspect ratio of a fiber is the ratio of its length to diameter (or thickness). A fiber can be defined as an elongated material having a more or less uniform diameter or thickness less than 250 µm and an aspect ratio greater than a hundred. This is an operational definition of fiber. This geometrical and useful definition of fiber applies to any material, and we can define other common terms related to fibers. These are in alphabetical order:

- Aspect ratio: The ratio of length to diameter of a fiber.

- Bicomponent fibers: A fiber made by spinning two compositions concurrently in each capillary of the spinneret.

- Continuous fibers: Continuous strands of fibers, generally, available as wound fiber spools.

- Cord: A relatively thick fibrous product made by twisting together two or more plies of yarn.

- Crimp: Waviness along the fiber length. Some natural fibers, e.g. wool, have a natural crimp. In synthetic polymeric fibers crimp can be introduced by passing the filament between rollers having teeth. Crimp can also be introduced by chemical means. This is done by controlling the coagulation of the filament to produce an asymmetrical cross-section.

- Denier: A unit of linear density. It is the weight in grams of 9000 m long yarn. This unit is commonly used in the US textile industry.

- Filament: Continuous fiber, i.e. fiber with aspect ratio approaching infinity.

- Monofilament: A large diameter continuous fiber, generally, with a diameter greater than 100 µm.

- Nonwovens: Randomly arranged fibers without making fiber yarns. Nonwovens can be formed by spunbonding, resin bonding, or needle punching. A planar sheet-like fabric is produced from fibers without going through the yarn spinning step. Chemical bonding and/or mechanical interlocking is achieved. Fibers (continuous or staple) are dispersed in a fluid (i.e. a liquid or air) and laid in a sheet-like planar form on a support and then chemically bonded or mechanically interlocked.

- Spinneret: A vessel with numerous shaped holes at the bottom through which a material in molten state is forced out in the form of fine filaments or threads.

- Spunbonding: Process of producing a bond between nonwoven fibers by heating the fibers to near their melting point.

- Staple fiber: Fibers having short, discrete lengths (10-400 mm long) that can be spun into a yarn are called staple fibers.

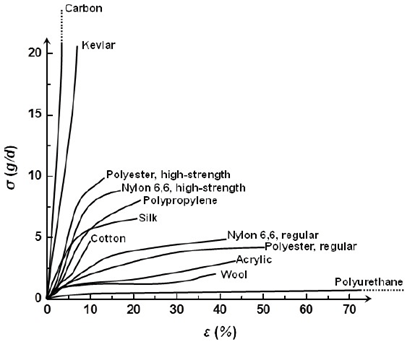

- Tenacity: A measure of fiber strength that is commonly used in the textile industry. Commonly, the units are gram-force per denier, gram-force per tex, or newtons per tex. It is a specific strength unit, i.e. there is a factor of density involved. Thus, although the tensile strength of glass fiber is more than double that of nylon fiber, both glass and nylon fiber have a tenacity of about 6 g/den. This is because the density of glass is about twice that of nylon.

- Tex: A unit of linear density. It is the weight in grams of 1000 m of yarn. Tex is commonly used in Europe. [2]

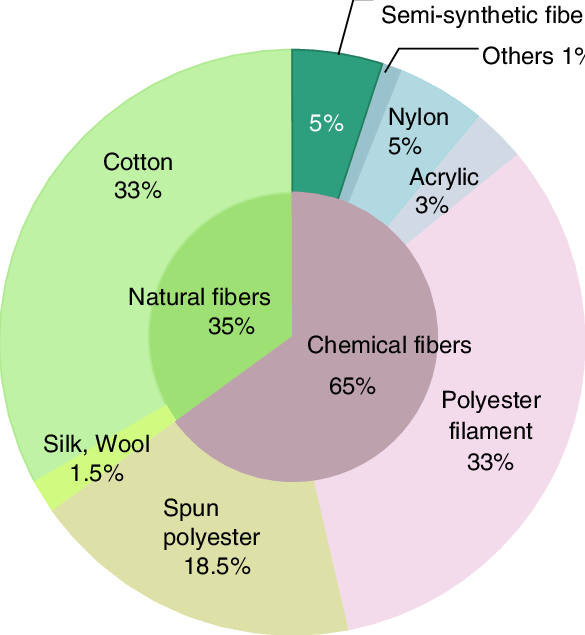

A wide range of polymers can be transformed into fibers (we will address this in later articles). These fibers have many important applications that make them simple to use in everyday and everyday applications to various industries and sophisticated and high-tech applications. The most important of these fibers are polyester, polyamide or nylon, polyolefin, acrylic, aramid and vinyl.

Polymer fibers are classified according to their performance into conventional and high performance fibers. In this article, we look at ordinary performance fibers and in the following article we look at high performance fibers.

1) Polyester Fibers

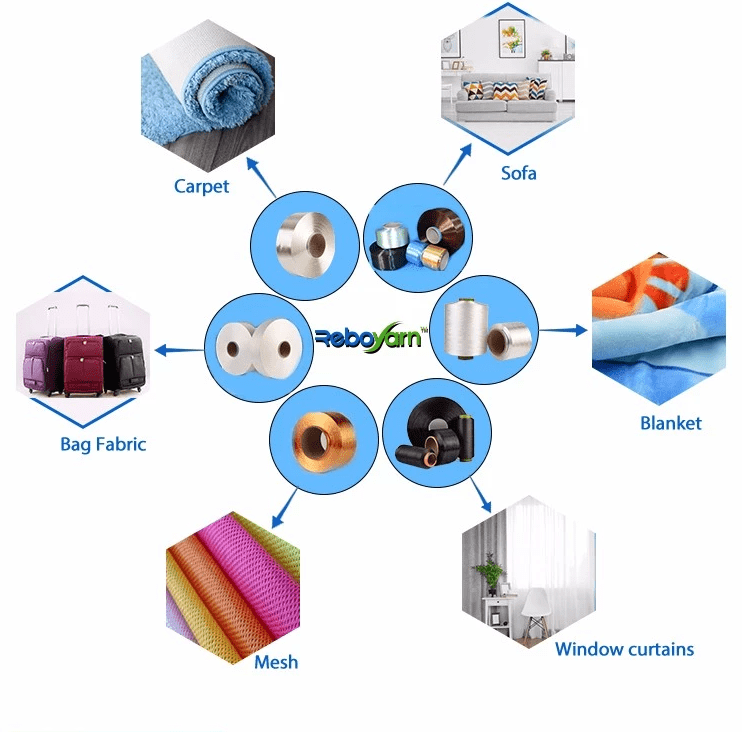

Polyester fibers, which mainly consist of polyethylene terephthalate (PET), make up a large volume of the world’s synthetic fiber industry products and somehow dominate the industry. These fibers are inexpensive and are easily obtained from petrochemical sources and have a good range of physical properties. They are durable, lightweight, easily paintable and resistant to wrinkles and have excellent washability. These fibers are used in both continuous and discrete fashion in textile and furniture fabrics, carpets, tires, car seat belts, filters, tents, sails and more.

Although the dominant polymer in these fibers is PET, other polyesters also have their place. Polybutylene terephthalate (PBT) and more recently polyethylene terephthalate (PTT) are used in carpet fibers due to their superior fiber resistance. [3]

Dacron was the first polyester introduced in 1953. It is a long chain polymer composed of 85% by weight an ester of dihydric alcohol and terephtalic acid.

2) Polyamide or Nylon Fibers

Due to their properties, these fibers are widely used in many fields and industries, especially the textile industry. We deal with each of these areas separately.

A) textiles

Nylon fibers have properties that make them one of the most popular synthetic fibers. These include high strength as a textile fiber; abrasion, luster, chemicals and oils resistance, water washability, dyeability in a wide range of colors, good elasticity and resilience, smooth, soft, long-lasting fabrics of filament yarns. Because of these properties of nylon fibers are widely used in clothing such as knitwear, socks, underwear, raincoat, ski clothing, windsurfing, swimming and cycling clothing, as well as for home furnishings such as furniture, Upholstery, rugs and curtains are used. A combination of excellent abrasion resistance, appearance and economic agents puts polyamide fibers in a great position in the carpet fibers market and it can be expected that these nylons will still be the most used fibers for carpets.

B) Industrial Applications

Excellent mechanical properties, fatigue resistance and good tensile strength are the reasons for the superiority of polyamide fibers for industrial applications and for use in truck and aircraft tires. Other uses of these fibers are upholstery fabrics, seat belts, parachutes, ropes, fishing line, nets, sleeping bags, tarpaulins, tents. In addition, high strength, toughness and wear resistance are key factors in the choice of polyamide fibers for a wide range of military applications.

C) Nonwovens

Nylon, like polyester fibers (PET), has a high melting point that works well at high temperatures. Nylon fiber is more sensitive to water than PET. In some cases it is used as a blend fiber because it has excellent tear strength. Overall, the resiliency and wrinkle recovery of a non-woven nylon product is not as good as PET fiber. Because of its toughness, nylon fibers are suitable for flooring.

Also used in Ni-H and Ni-Cd batteries as separators, synthetic suede, thermal insulation, special paper, automotive products, sportswear and conveyor belts.

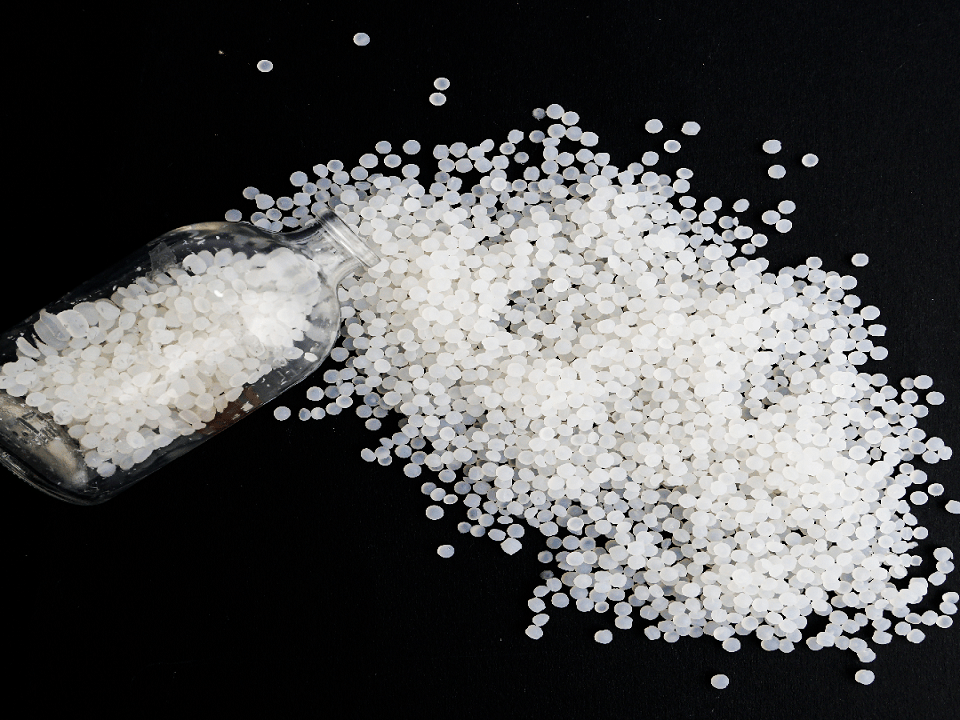

3) Polyolefin Fibers (Polyethylene and Polypropylene)

With the exception of carbon, glass, metal and ceramic fibers, most natural or synthetic fibers in general commercial use are organic structures with a carbon-carbon chain backbone. Basically polyolefin polymers have high molecular mass, aliphatic and saturated hydrocarbons, some of which can be easily fused.

A typical polyolefin fiber density range is from 0.90 to 0.96 gr/cm3 and shows extremely low moisture regain. Polyolefin fibers, thus, are suitable choices for applications requiring aquatic buoyancy and negligible moisture regain, such as mooring ropes, oil spill booms, and fishing nets, etc.

Polyolefin fibers have good tensile properties, good abrasion resistance and excellent resistance to chemicals, mildew, micro-organisms, and insects. Polyolefin textile structures show good wicking action, high insulation and are comfortable to the skin, which are significant factors for active sportswear and protective clothing.

However, polyolefins have problematic properties for specific applications. For example, due to the low melting point, polyethylene C125-120 ° C and polypropylene C165-160 ° C cannot be used at high temperatures. These fibers are not usable on exterior surfaces; since polyolefins are susceptible to photosynthetic degradation, they have low resistance to dehydration at temperatures above 100 ° C, are difficult to dye and have limited shade of color. The olefins also have high flammability, low resilience, and stress-induced creep.

Use of polyolefin fibers in medical textiles

Polyolefin, PP in particular, exhibits excellent chemical resistance and chemical inertness. These properties are prerequisites for medical and surgical applications. Fibrous structures for medical applications also require a combination of strength, flexibility, and controlled moisture and air permeability. Materials for these applications can be classified into four specialized areas:

- non-implantable materials – wound dressing, bandages, plasters, etc.

- extracorporeal device – artificial kidney, liver and lung

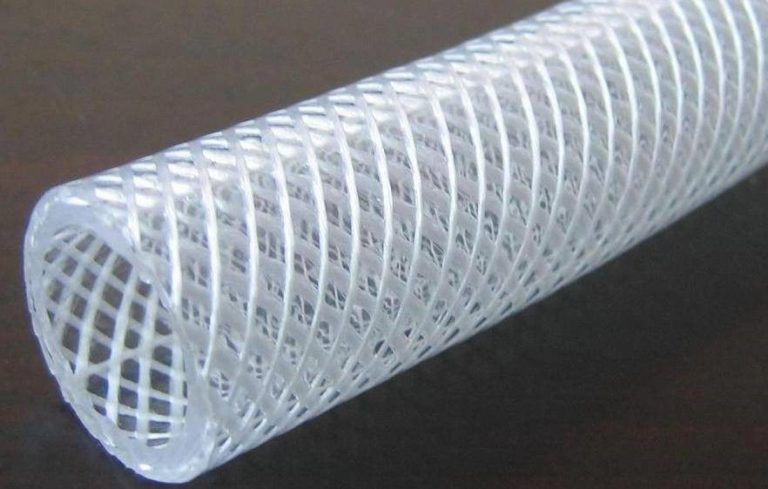

- implantable materials – sutures, surgery meshes, vascular grafts, artificial joints, artificial ligaments

- healthcare/hygiene products – bedding, diaper, surgical gowns, wipes, etc.

For non-implantable material applications, knitted, woven or nonwoven polyethylene fabrics are used in wound contact areas and wound care products. In some orthopaedic bandages, woven or nonwoven fabrics made of polypropylene fibers are used. Knitted, woven, or nonwoven polypropylene fabrics can serve as reinforcements for plasters.

For implantable applications, non-bioabsorbable sutures are typically made of PP fibers by braiding. Surgery meshes, for example hernia meshes.

Healthcare/hygiene products are mainly based on PP nonwovens. The largest single fiber application for PP is nonwoven fabrics. There are three different types of nonwoven structures of PP for this application: spunbonded (SB), melt-blown (MB) and thermal-bonded carded webs. The latter is mainly used for diaper linings in a similar fashion to SB nonwovens. Disposable diaper and incontinence control applications are the largest single PP nonwoven fabrics market.

Hospital gowns, uniforms, and surgical gowns are mainly disposable because of the high cost of laundering and sterilization. Thus, PP nonwovens are ideal for this application. Many hospital garments are made of SMS PP nonwoven composites, in which the added barrier membranes are incorporated in the middle layer to prevent the passage of blood-borne pathogens or disease-causing microbes [16]. In addition, PP nonwovens are a major component of wipes and beddings used in healthcare facilities. Hollow PP fibers are used in mechanical lungs to remove carbon dioxide from patients’ blood and supply fresh blood.

Use of polyolefin fibers in filtration

A wide variety of industrial processes requires the separation of solids from

liquids (suspension) or gas (aerosol) for purifying products, saving energy raising process efficiency, recovering precious materials, and improving pollution control system, etc. For example, air filters are used for separating suspended solid particles (soot) or liquid droplets (aerosol) in air. Filter media fabric design must be based on the performance properties such as the length of service life, physical and chemical condition of the operation. The design criteria cannot be overemphasized because filter fabric failure during service could result in lost production cost, loss of product,

heavy maintenance cost and added environmental pollution. The fibrous filter media are fabricated in woven, knitted, nonwovens or their combinations to meet the performance criteria. Filtration mechanisms are: interception, inertial deposition, Brownian motion, electrostatic, and gravitational. One of the earliest applications for polyethylene yarns was in the production of industrial filtration fabrics. The range of properties offered by polyethylene is particularly suitable for this application, and PE fiber is being used increasingly for this purpose. The polyethylene yarns are used for industrial filtration fabrics owing to the following features:

- The high wet strength of PE fibers and PE fabrics are not weakened during the filtration of water solutions.

- The excellent resistance of polyethylene to a wide range of chemicals and solvents used for filtration of industrial liquids.

- The high abrasion resistance of polyethylene enables the fabrics to withstand considerable abrasion during filtration.

- Polyethylene is particularly good in cake release. Solid particles are built up into cakes between the layers of filters during the filtration of industrial liquids. These cakes are removed perhaps many times a day by opening the filter presses, and it is important that the solid material should come away cleanly and easily from the filter fabric.

- The complete resistance of polyethylene to attack by micro-organisms is of great value in many filtration applications, such as the filtration of sewage.

- Dimensional stability.

- Low cost. [5]

4) Acrylic Fibers

Most of the growth in the use of acrylic fibers is due to its replacement with wool. Acrylic has many of the desired properties of wool, yet it is superior in many areas where wool is deficient. Acrylic fibers such as wool are valuable because of their warmth, softness of hand, generous bulk and pile qualities, and ability to recover from stretching. Acrylics, meanwhile, are less expensive, more resistant to abrasion and chemical attack, and more stable toward degradation from light and heat. In addition, acrylics are not attacked by moths and biological agents and show very little of wool’s tendency to felt. [4]

Acrylics, in stiff competition with nylon, polyester and polyolefin, have penetrated only markets where they have a clear advantage in critical properties. For example, acrylics are clearly superior in resistance to sunlight. This makes continuous filament acrylics valuable in outdoor applications, such as convertible tops, tents, and awnings. Pigmented acrylics can be used in applications where maximum resistance to fading and loss of strength is needed. [4]

In applications such as awnings that require high flame resistance, modacrylic fibers are used. Acrylics with low comonomer content are highly resistant to chemical attack and thermal degradation. These properties make acrylics suitable for industrial filters and battery separators. [4]

In the general apparel market, acrylic and modacrylic fibers are used as artificial fur or fur-like fabrics. These fibers are made in coarse deniers with special cross sections and surface modifications (e.g., surface inclusions or roughening) to simulate natural animal hairs. Uniform fabrics and silky fabrics are also produced from continuous filament acrylic and modacrylic yarns. [4]

5) Vinyl Fibers

A) Polyvinyl Alcohol (PVA) or Vinylon Fibers

One of the characteristic properties of PVA fiber is its high affinity to water. Its strength, modulus and toughness are not much different from those of conventional fibers. However, the main weaknesses of vinylon fiber are that it is not thermoplastic and exhibits little elastic recovery, although it is superior in these areas to cotton and rayon.

In the industrial fields, the vinylon spun yarns prepared by the perlok spinning system are used for various purposes such as ropes, fishery materials, industrial sewing threads, bicycle tire cords, hoses (fire hose, braided hose), sheets, industrial heavy fabrics, agricultural materials, etc. The vinylon spun yarns prepared by cotton-spinning systems are used typically in the manufacture of sheets, tents, sporting goods, rubbery soled cloth shoes, coated fabrics with polyvinyl chloride, fertilizer bags, warp yarns of tatami mats, and so on.

The industrial uses of vinylon filament yarn include laver cultivating nets, conveyor belts, radial tire cords, sewing threads for tatami mats, canvas and duck, base cloths, reinforcing fibers, hoses and so on. Its new applications are in the field of civil engineering industry as reinforcing materials (geotextiles). [4]

B) Polyvinyl Choloride or Vinyon Fibers

The most characteristic property of PVC fiber is its non-flammability, which leads to its many applications. The PVC fiber is thermoplastic, highly resistant to water, and shows insulating properties to electricity and heat. Its disadvantages are its low softening temperature and low tenacity. [4]

Finally, the physical and mechanical properties of polymer fibers are presented in the table below:

Table 1. Physical and Mechanical Properties of Polymer Fibers

| Fiber | Density | Tenacity | Modulus | Strain at break | Moisture Retention | Elastic Retention at % Strian |

| Unit | gr/cm3 | gr/denier | gr/denier | % | % | % |

| Polyethylene (HDPE) | 0.95 | 4.5-8 | 30 | 10-20 | 0 | 0 |

| Polypropylen | 0.9-0.91 | 2-7.8 | 50-90 | 15-50 | 0 | 100 at 2% |

| Acrylic | 1.14-1.19 | 2-3.6 | 40-75 | 25-55 | 1.3-2.5 | 85-99 at 2% |

| Polyamide | 1.14 | 4.3-6 | 16-40 | 15-40 | 3.5-5 | 80-99 at 2% |

| Polyester | 1.38 | 9 | 125 | 25 | 0.4 | 100 at 8% |

| Vinylon | 1.28-1.30 | 4-6.5 | 25-70 | 12-26 | 4.5-5 | – |

| Vinyon | – | 2-2.8 | 15-25 | 15-23 | 0 | – |

Sources:

[1]. Xiangwu Zhang, Fundamentals of fiber science, DEStech Publications, Inc., 2014

[2]. K.K.Chawla, Fibrous Materials, Cambridge University Press, 2005

[3]. J. E. McIntyre, Synthetic fibres: Nylon, polyester, acrylic, polyolefin, Woodhead Publishing Limited, 2005

[4]. Menachem Levin, Handbook of Fiber Chemistry, Taylor & Francis Group, LLC, 2007

[5]. Samuel C. O. Ugbolue, Polyolefin Fibres, Industrial and medical applications, Woodhead Publishing Limited, 2009

[6]. https://www.researchgate.net/figure/World-fiber-production-distribution-FY2013-Fiber-Handbook_fig3_321906085

[7]. https://www.alibaba.com/product-detail/PET-bottles-recycled-polyester-staple-fiber_60287036235.html

[8]. https://zjhaili.en.alibaba.com/product/60633459443-803693685/333dtex_72f_Bright_Recycle_Polyester_Yarn_POY.html

[9]. https://www.geotextile-fabrics.com/products/geotextile-fabric/short-fiber-geotextile-fabric.html

[10]. http://www.str-ucture.com/en/what/construction-projects/reference/car-park-roofing-bochum-germany-2009/

[11]. http://tqf.cc/nylon-carpet-fibers/

[12]. https://www.alibaba.com/product-detail/Nylon-triangle-fiber_268111882.html

[13]. http://syntechfibres.com/application-areas/

[14]. https://www.usbiodesign.com/biomedical-textile-specialties/general-surgery

[15]. https://4.imimg.com/data4/LV/JT/MY-598948/polypropylene-fibers-500×500.jpg

[16]. https://sc02.alicdn.com/kf/HTB1sltCdVGWBuNjy0Fbq6z4sXXaw/polyethylene-fibers-for-concrete.jpg_350x350.jpg

[17]. https://www.alibaba.com/product-detail/Stock-Lot-of-Loose-Acrylic-Fiber_50029846015.html

[18]. https://www.extremeterrain.com/bestop-trektop-nx-glide-softtop-blktwill-0717-2door-jeep.html#product_pics-0

[19]. https://www.amazon.com/Awntech-Maui-LX-Retractable-Projection-Burgundy/dp/B00GDLS24G

[20]. http://www.covinfabrics.com/agora.html

[21]. https://www.ebay.com/itm/Vintage-TISSAVEL-France-Pile-100-Acrylic-Faux-Fur-Jacket-Women-s-Medium-/264365038428

[22]. https://apexnewsroom.com/global-polyvinyl-alcohol-fiber-vinylon-fiber-market-xiangwei-ningxia-dadi-stw-minifibers/4565/

[23]. https://www.ecplaza.net/products/pvc-fibre-reinforced-hose_373193

[24]. https://teletype.in/@meera/SJu3VlesS

Compiled by:

Hamidreza Tayari

Key words: polymer fiber, polyester, acrylic, polyolefin, vinyl, vinylon, vinyon, polyamide, nylon, synthetic fiber, man-made fiber

2 Comments

Heya fantastic website! Does running a blog like this take a massive amount work?

I’ve virtually no understanding of coding however I was hoping to start my own blog

soon. Anyway, should you have any ideas or

tips for new blog owners please share. I know this is off subject but I just

wanted to ask. Thanks!

Thank you for your attention