Optimized compatibilizer in glass fiber filled-polypropylene compounds (PP/GF): SEBS-g-MA, POE-g-MA or PP-g-MA?

Effect of PP-g-MA on mechanical properties PP/GF

Optimized compatibilizer in glass fiber filled-polypropylene compounds (PP/GF): SEBS-g-MA, POE-g-MA or PP-g-MA?

Using compatibilizers is a common approach to intensify the effect of reinforcing fillers such as glass fiber in plastic (esp. PE or PP) compounds to improve the properties. But how?

Polypropylene is an important polymer in plastic industry. Recently it has been applied in many applications such as electronic, construction and automotive products due to its proper process characteristics, high chemical stability and electrical insulation. However low mechanical and thermal properties of PP can cause limitation to be used in some applications. Numerous researches have been done to increase the mechanical properties of PP by adding reinforcing fillers. Among the reinforcing materials, glass fiber has an important position to enhance the mechanical strength of PP. This approach can be completed by using compatibilizer in compounds by eliminating the poor interfacial adhesion between components.

But which compatibilizer can be used in PP/GF more effectively? The simple comparison between the common compatibilizers, SEBS-g-MA, POE-g-MA or PP-g-MA, has been reviewed in this article. The impact strength and tensile strength are considered as criteria for mechanical properties.

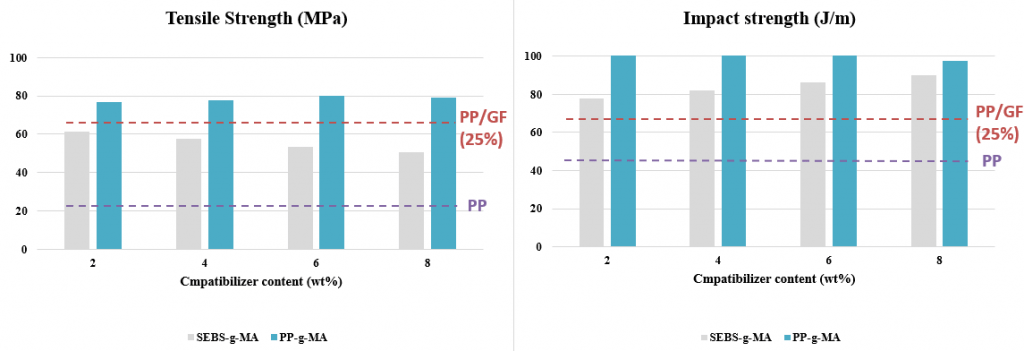

1.PP-g-MA or SEBS-g-MA?

Based on Fig.1, the opposite effect is resulted by comparing the tensile and impact strength of PP/SGF in different amounts of compatibilizers. The results show that the addition of a PP-g-MA and SEBS-g-MA improves the impact strength with different intense. However the SEBS-g-MA has negative effect on tensile strength of the PP/GF compounds due to the nature of the SEBS as a thermoplastic elastomer. Thus the PP-g-MA in optimum content is more effective than SEBS-g-MA in mechanical strength since it has no rubbery manner and also better compatibility in PP/GF compounds.

(Data from Polypropylene/Short Glass Fibers Composites: Effects of Coupling Agents on Mechanical Properties, Thermal Behaviors, and Morphology by JH Lin, 2015)

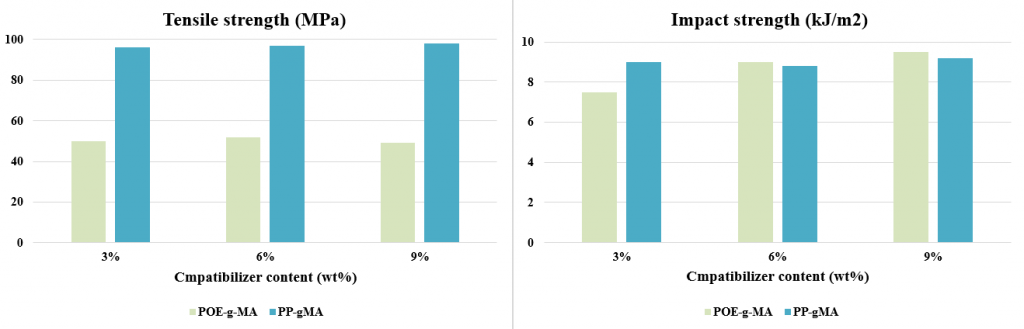

2- PP-g-MA or POE-g-MA?

Based on Fig.2, both compatibilizers are effective in enhancing the impact properties. However, unlike the PP-g-MA, POE-g-MA increases the impact strength with drastic reduction in the tensile strength. Similarly, the PP-g-MA in optimum content is more effective than POE-g-MAH with the same reason.

(Data from Effects of Compatibilizers on Mechanical Properties of Long Glass Fiber-Reinforced Polypropylene by X Fu, 2010)

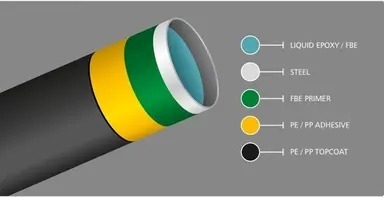

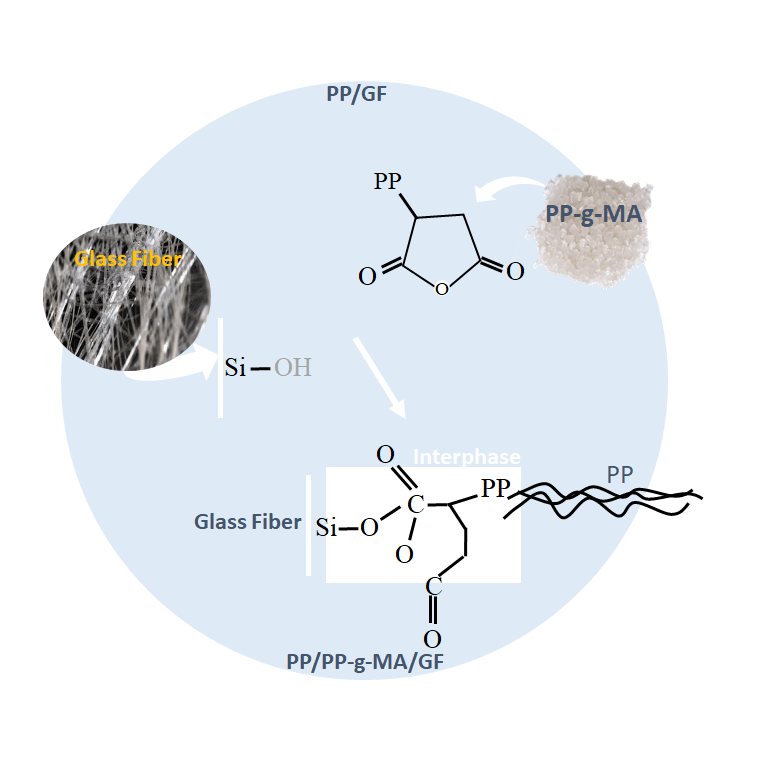

Therefore, it seems that PP-g-MA is a good option to be applied as compatibilizer or coupling agent in PP/GF compounds. The PP-g-MA is able to make covalent bonds with function groups of GF and also leads to strong interphase due to its compatibility with matrix. Chemical reaction between PP-g-MA and GF is shown in Fig.3. This compatibility at the interphase can absorb the energy and show well impact resistance. Also the resulted interphase improve toughness without sacrificing rigidity and stability of their shape.

Thus PP/PP-g-MAH/GF can be very useful compounds using in automotive and electronic parts. Aria Polymer company is manufacturer of various compatibilizers applying in engineering plastic such as filled PE or PP compounds like PP/GF. For more information, contact us by en.ariapolymer.ir.