Multilayer Films for Food Packaging: The Manifestation of Interlayer Adhesives

Multilayer Films for Food Packaging: The Manifestation of Interlayer Adhesives

In the article of properties of different types of polymers at polymer films (part one) has mentioned to importance of polymer films at packing industrial and applications of them in this industry. One of the most important categories of polymer films is multilayer films. Significant purposes of combination of polymers in multilayer films is to preserve the quality of food materials and also to prevent them from moisture and oxygen [1].

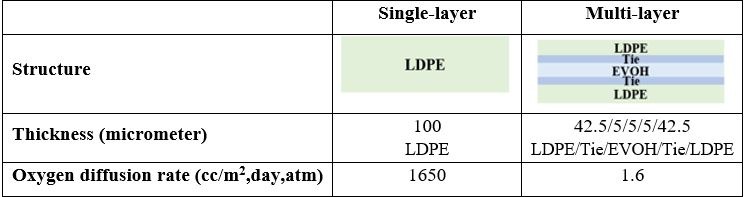

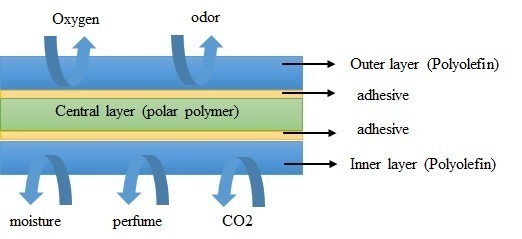

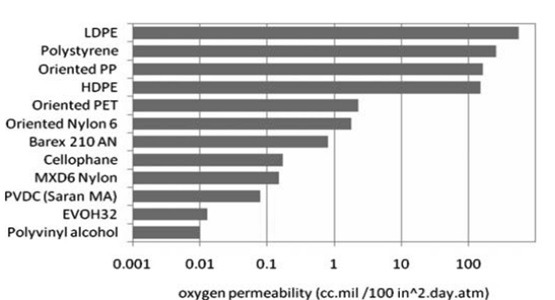

Based on the features that is said above in this article, polyolefins are considered very useful. Although these materials have some benefits such as: processing, no moisture diffusion, good thermal and mechanical properties, but polyolefins do not have suitable resistance to oxygen diffusion. Unlike the polyolefins, a polar polymer like ethylene vinyl alcohol copolymer (EVOH), due to its chemical structure has resistance against diffusion of oxygen, so this material because of recycling ability and transparency is replacing instead of metalized films and aluminum foils. Based on the data of table1, adding EVOH to the center of multilayer film (the middle layer) leads to remarkable resistance against oxygen in comparison to a single-layer of polyolefins (e.g. LDPE) [1].

Table1: Comparison of oxygen diffusion rate between single-layer and multi-layer films [2].

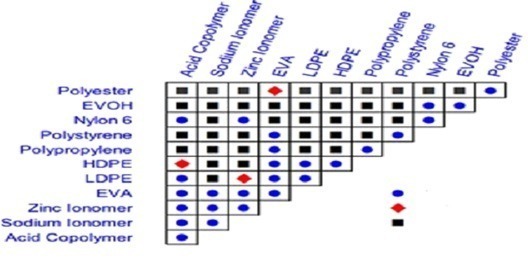

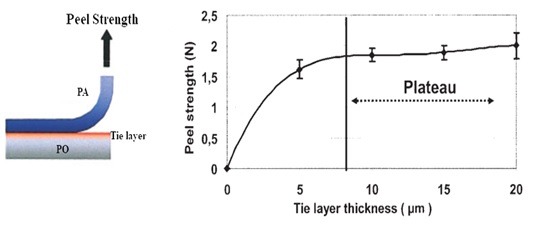

However, mixing of polar polymers like EVOH and non-polar polymers such as Polyethylene (PE) because of incompatibility is challenging. That is why to make multi-layer films with this combination need to use of new generation of adhesives which is called interlayer adhesive or Tie layer to promote weak adhesion between the layers.

– Properties of packaging films:

Packaging films must have four functions:

- Chemical and thermal stability

- Moisture resistance and oxygen diffusion resistance

- High mechanical properties (abrasion, impact and volume stability)

- Qualified optical properties such as transparency and brilliance

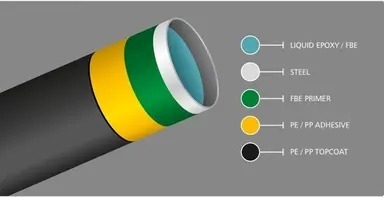

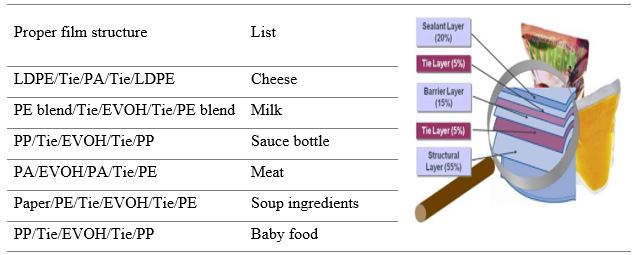

As mentioned above, the main goal of compounding polymers in multi-layer films is preserving the quality of food materials and prevent from exposureing to moisture and oxygen. Due to appropriate properties and resistance against the diffusion of oxygen polyolefins play an essential role in making multi-layer films. Nevertheless, for creating resistance against oxygen diffusion in these multi-layer films it is used from polar polymers such as polyamide or EVOH in the central layer of the films. Fig. 1 shows the regular structure of an ideal film at packaging film industry. Combination of polyolefin layer with the polar polymer layer makes the film resistant in both moisture and oxygen. Such a film with preventing of oxygen diffusion and the other gases would prevent from food spoiling and it can take care of the quality of food with keeping the scent and moisture.

Fig.1.Function of ideal multi-layer film in food- packaging industrial [3]

Fig. 2. Oxygen permeability of some polymers [4]

Fig. 3. Combability of different materials [5].

Fig. 4. Adhesion strength between layers [5].

Fig. 5. Interaction of adhesive and polar polymer mechanism (covalent bonding) [6].

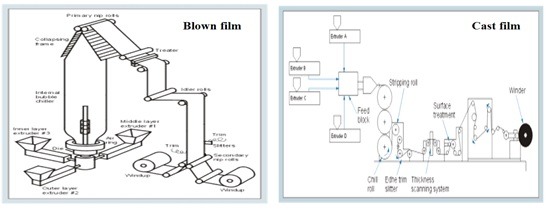

Fig. 6. Methods of producing multi-layer films by co-extrusion process [6].

Fig. 7. Changes in adhesion by different factors [7].

Table 2. Suitable packaging film for various food grade.

Finally, to select an appropriate adhesive, we should consider the layers of a film, the strength which is needed, physical requirements, cost and processing factors. In addition, interlayer adhesive components must be designed in a way to make a good balance between adhesion with transparency and flexibility.

Fig. 8. Non-flexible films (on the left) and resistant films against oxygen diffusity (on the right) [8].

Author: Emad Izadi Vasafi

References:

[1] Maes, C. Luyten, W., Updates on the Barrier Properties of Ethylene Vinyl Alcohol Copolymer (EVOH): A Review. Polymer Reviews 2018, 58, 209–246.

[2] Sangaj, N.S. and V. Malshe, Permeability of polymers in protective organic coatings. Progress in Organic coatings, 2004. 50(1): p. 28-39.

[3] Mokwena, K.K. and J. Tang, Ethylene vinyl alcohol: a review of barrier properties for packaging shelf stable foods. Critical reviews in food science and nutrition, 2012. 52(7): p. 640-650.

[4] Morris, B.A., Tie layer technology for multilayer coextrusion of single-use biopharma bags. 2017.

[5] Poisson, C., et al., Optimization of PE/binder/PA extrusion blow‐molded films. II. Adhesion properties improvement using binder/EVA blends. Journal of applied polymer science, 2006. 101(1): p. 118-127.

[6] Ebnesajjad, S. and C. Ebnesajjad, Surface treatment of materials for adhesive bonding. 2013: William Andrew.

[7] Butler, T.I. and B.A. Morris, PE-based multilayer film structures, in Multilayer flexible packaging. 2016, Elsevier. p. 281-310.

[8] Kamykowski, G.W., Factors affecting adhesion of tie layers between polypropylene and polyamides. Journal of Plastic Film & Sheeting, 2000. 16(3): p. 237-246.